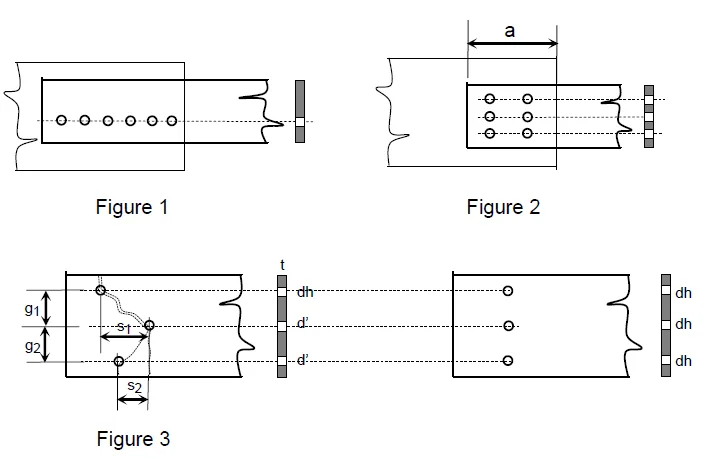

Staggered Fasteners

In tension member connections with bolts, the net area is largest when fasteners are placed in a single line. However, space constraints often require multiple rows of bolts. To reduce the loss of cross-sectional area, bolts can be arranged in a staggered pattern, where holes do not line up directly. This arrangement ensures that any potential failure plane passes through fewer bolt holes, helping maintain strength and efficiency compared to non-staggered layouts.

Staggered Connection Figures

Cochrane's Formula for Staggered Connections with Uniform Thickness

Cochrane (1922) proposed that when deducting the area corresponding to a staggered hole, a reduced diameter d′ should be used, given by:

The net width, bn, is then:

The net area, An, is:

Where:

s = pitch (horizontal distance between adjacent bolts)

g = gauge (vertical distance between adjacent bolts)

dh = diameter of hole

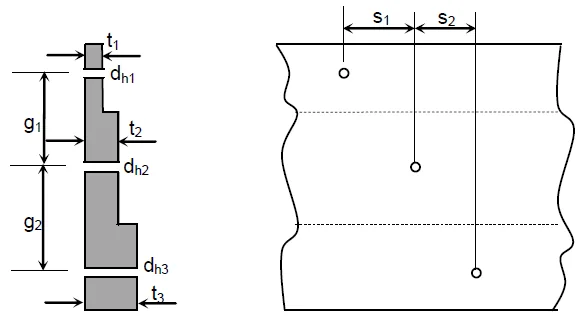

Cochrane's Formula for Staggered Connections with Non-Uniform Thickness

The tension member below illustrates a connection in which holes are made on different elements with different thicknesses.

The equation of the net area becomes:

The equation of the net area becomes: