Plastic Analysis (Collapse Mechanism)

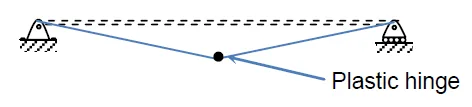

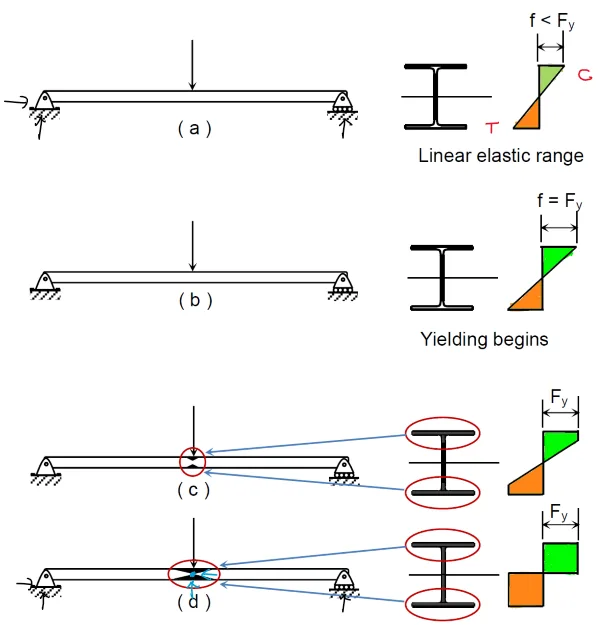

When all elements of the beam's cross-section have yielded, any further increase in load will cause collapse. At this stage, the beam has reached the yield plateau of the stress→strain curve, and unrestricted plastic flow will occur. A plastic hinge forms, and together with the actual hinges at the beam ends, they constitute an unstable mechanism.

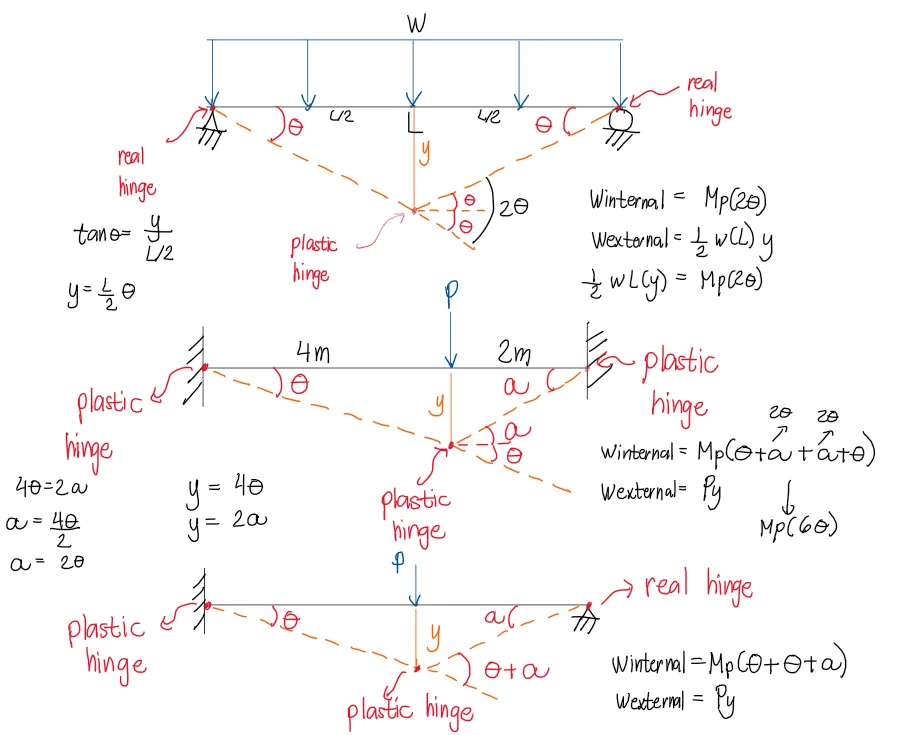

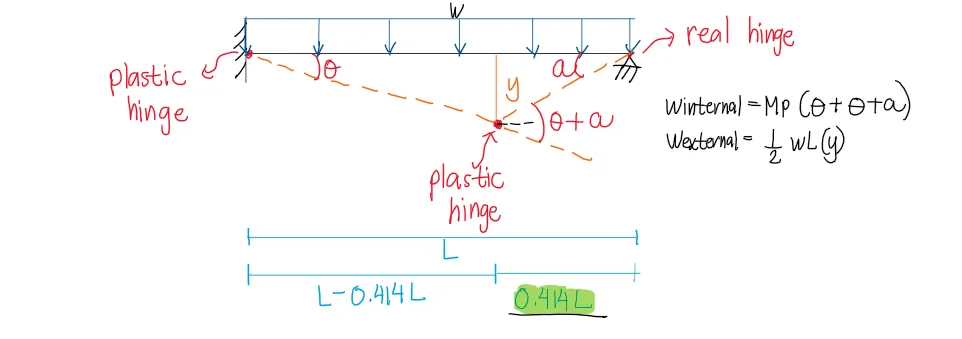

Structural analysis based on collapse mechanism is called plastic analysis. This method applies the principle of virtual work, where an assumed mechanism is subjected to virtual displacements consistent with the mechanism's motion, and the external work is equated to the internal work.

Before solving plastic analysis problems, recall some principles of the virtual work method:

External Work:

-

Work done by a force $P$ that varies linearly with displacement $y$ from zero to its final value:

$$ W = \tfrac{1}{2} P y \quad (1) $$

-

Work done by a constant force $P$ while its point of application undergoes displacement $y$:

$$ W = P y \quad (2) $$

Internal Work:

Major Cases in Plastic Analysis

Recall:

When all the elements of the cross-section of the beam has yielded, any further increase in the load will cause collapse, since all elements of the cross-section reached the yield plateau of the stress-strain curve and unrestricted plastic flow will occur.

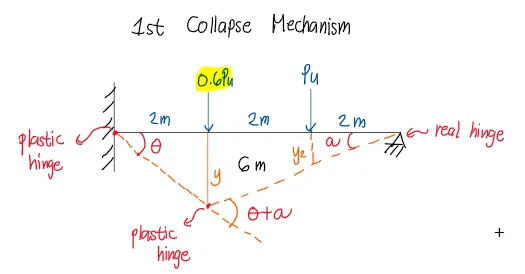

$$ \frac{y}{4} = \frac{y_2}{2} $$

$$ y_2 = \frac{2}{4}y $$

$$ y_2 = 0.5y $$

$$ 2\theta = 4\alpha $$

$$ \alpha = \frac{2}{4}\theta $$

$$ \alpha = 0.5\theta $$

$$ \tan\theta = \frac{y}{2} $$

$$ 2\theta = y $$

$W_{ext} = W_{int}$

$ 0.6P_u(y) + P_u(0.5y) = M_p(\theta + \theta + \theta_a) $

$$ \frac{y}{4} = \frac{y_2}{2} $$

$$ y_2 = \frac{2}{4}y $$

$$ y_2 = 0.5y $$

$$ 2\theta = 4\alpha $$

$$ \alpha = \frac{2}{4}\theta $$

$$ \alpha = 0.5\theta $$

$$ \tan\theta = \frac{y}{2} $$

$$ 2\theta = y $$

$W_{ext} = W_{int}$

$ 0.6P_u(y) + P_u(0.5y) = M_p(\theta + \theta + \theta_a) $ $$\frac {y}{4}=\frac {y_2}{2}$$

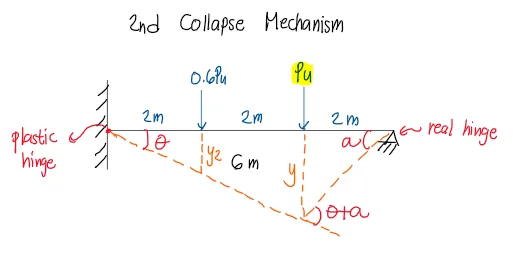

$$y_2=0.5y$$

$$2\alpha=4\theta$$

$$\alpha=2\theta$$

Therefore, $$y=4\theta$$

$W_{ext} = W_{int}$

$$\frac {y}{4}=\frac {y_2}{2}$$

$$y_2=0.5y$$

$$2\alpha=4\theta$$

$$\alpha=2\theta$$

Therefore, $$y=4\theta$$

$W_{ext} = W_{int}$