Beam Bearing Plate and Column Base Plate

Plates distribute concentrated loads to the supporting material. A beam transfers its reaction to a supporting wall or to the top flange of a girder, while a column transfers its load to a concrete pedestal. Below is a design outline for a beam bearing plate;

A. Beam Bearing Plate

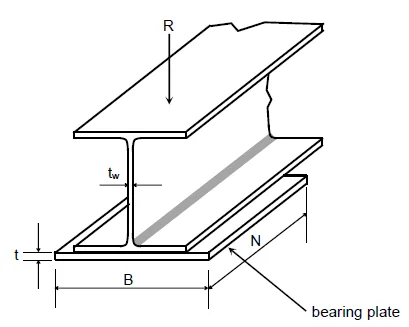

Designing the bearing plate involves finding its width $B$, length $N$, and thickness $t$ (see figure).

Step 1 — Choose $N$ to prevent web yielding and web crippling

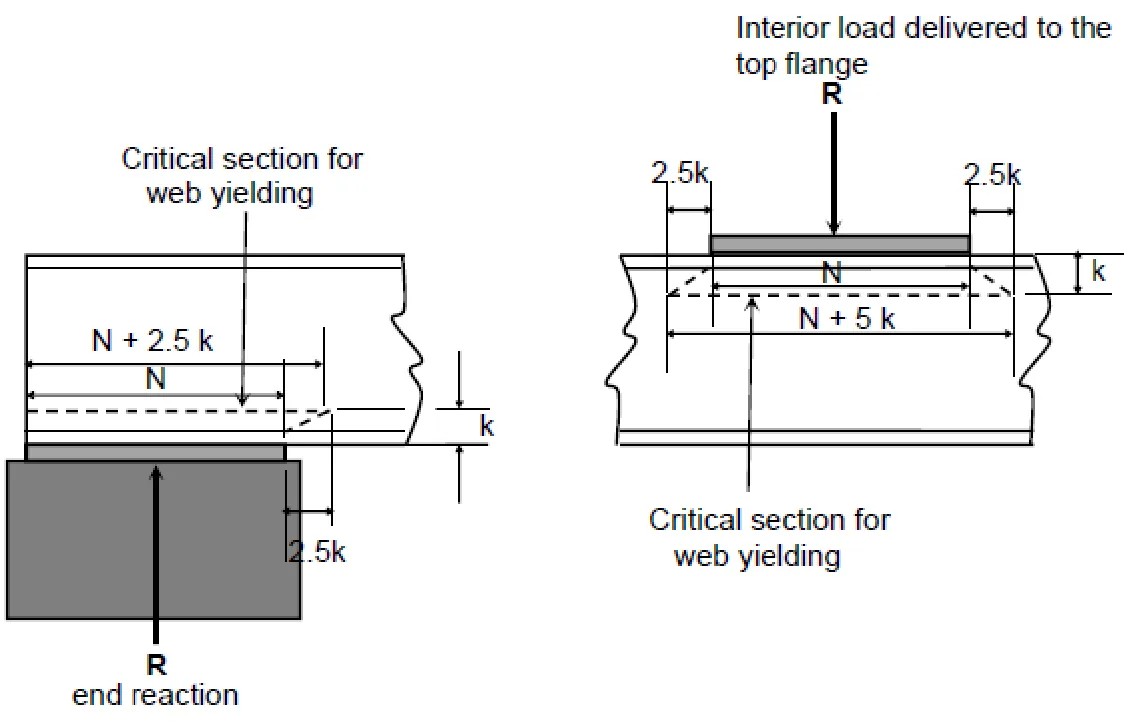

Web yielding. Load spreads through the web at an approximate $1:2.5$ slope. The area in yielding and the nominal strength are:

• At a support:

• At an interior load:

Design/allowable strengths:

Web Crippling

Buckling of the web caused by concentrated compression through the flange. Use the applicable web-crippling expressions (end reaction and interior reaction); select the case based on whether the load is near the end (within $d/2$) or interior.For a load at or near the support (within $d/2$ of the end):

• When $N/d \le 0.20$

• When $N/d > 0.20$

For an interior load, the nominal strength is:

For LRFD, $\phi = 0.75$ and for ASD, $\Omega = 2.00$.

Step 2 — Choose $B$ so concrete (or supporting material) does not crush in bearing

AISC bearing strength for concrete:

• Plate fully covering the support:

• Plate not covering the full support:

Where: $f'_c$ = concrete compressive strength;

$A_1$ = bearing area under the plate;

$A_2$ = area of the support geometrically similar and concentric with $A_1$.

Design/allowable:

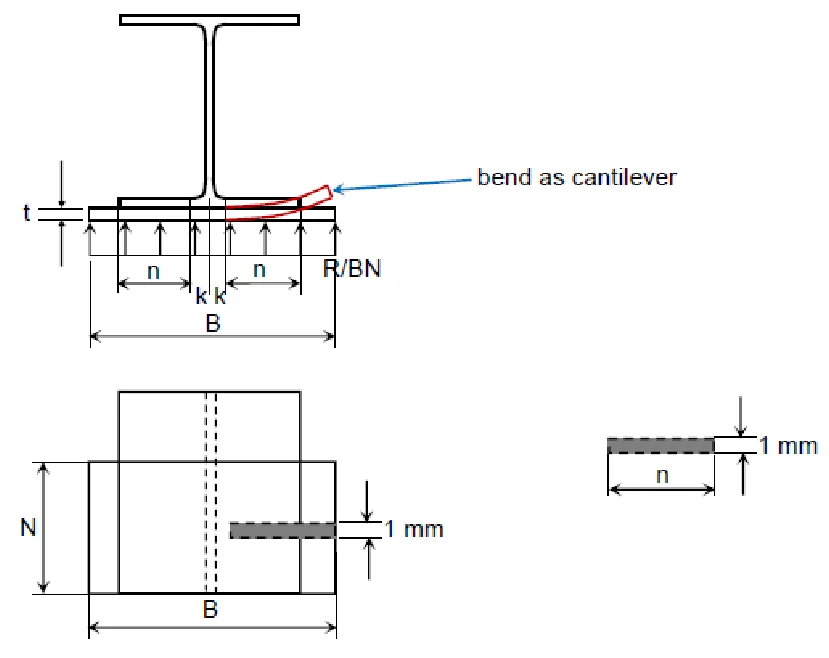

Step 3 — Choose thickness $t$ for plate bending strength

Treat a $1\,$mm strip of plate as a cantilever of span $n$ (see figure). With uniform pressure $R/(B N)$, the strip bending moment is:

Plastic moment capacity of a rectangular strip of thickness $t$:

LRFD thickness. Equate $M_u=\phi_b M_p$ with $\phi_b=0.90$ and solve for $t$:

ASD thickness. Equate $M_p/\Omega_b = M_a$ with $\Omega_b=1.67$ and solve for $t$:

Symbols:

$B$ = plate width;

$N$ = plate length (load length);

$t$ = plate thickness;

$t_w$ = web thickness;

$k$ = fillet distance from flange face to web toe;

$d$ = beam depth;

$R_u, R_a$ = factored/allowable reaction;

$F_y$ = steel yield stress;

$E$ = modulus of elasticity;

$\phi, \Omega$ = resistance/safety factors.